Intro

Master the art of metal cutting with 7 essential torch settings. Learn how to adjust gas flow, flame type, and pressure to achieve precise cuts, clean edges, and minimal distortion. Perfect your technique with expert tips on shielding gas, preheating, and more, and take your metalworking skills to the next level.

Cutting with a torch can be an intimidating task, especially for beginners. However, with the right techniques and settings, you can achieve professional-looking cuts with ease. In this article, we'll explore the 7 essential torch settings for cutting, helping you to improve your skills and confidence.

When it comes to cutting with a torch, the key to success lies in finding the perfect balance between heat, speed, and technique. The right settings can make all the difference, allowing you to cut through various materials with precision and accuracy.

Understanding Torch Settings

Before we dive into the essential torch settings for cutting, it's essential to understand the different components of a torch setting. These include:

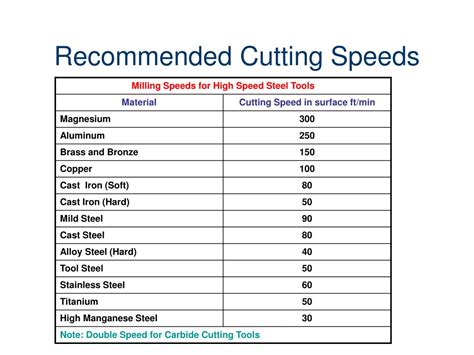

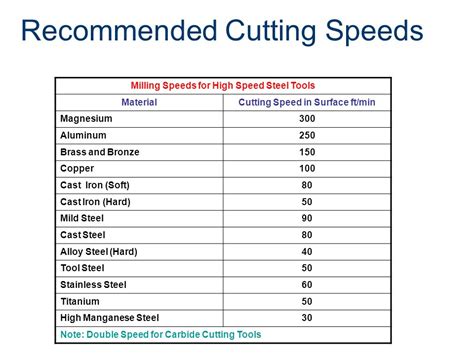

- Cutting speed: The rate at which you move the torch along the material.

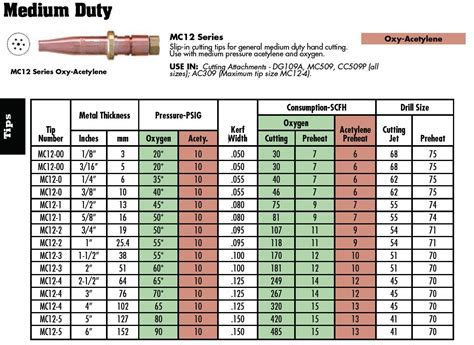

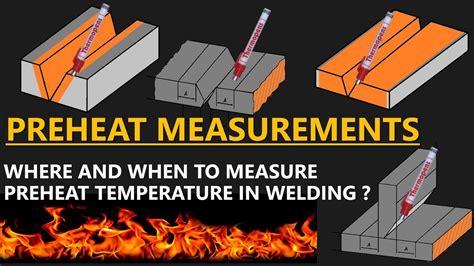

- Preheat temperature: The temperature at which the torch is set before starting the cut.

- Cutting temperature: The temperature at which the torch is set during the cutting process.

- Shielding gas: The type of gas used to protect the cut area from atmospheric gases.

1. Torch Angle

The torch angle is critical when it comes to cutting with a torch. A 20-30° angle is ideal for most cutting applications, allowing you to maintain control and achieve a smooth cut.

Benefits of the Right Torch Angle

- Improved control and precision

- Reduced risk of accidents and injuries

- Better cutting quality and finish

2. Cutting Speed

The cutting speed will depend on the material you're working with, as well as the desired level of precision. A slower cutting speed is often required for thicker materials or more intricate cuts.

Benefits of the Right Cutting Speed

- Increased accuracy and precision

- Reduced risk of overheating or warping the material

- Improved cutting quality and finish

3. Preheat Temperature

The preheat temperature is essential for achieving a smooth and even cut. A higher preheat temperature may be required for thicker materials or for cutting through tough or rusty surfaces.

Benefits of the Right Preheat Temperature

- Improved cutting quality and finish

- Reduced risk of overheating or warping the material

- Increased efficiency and productivity

4. Cutting Temperature

The cutting temperature will depend on the material you're working with, as well as the desired level of precision. A higher cutting temperature may be required for thicker materials or for cutting through tough or rusty surfaces.

Benefits of the Right Cutting Temperature

- Improved cutting quality and finish

- Reduced risk of overheating or warping the material

- Increased efficiency and productivity

5. Shielding Gas

The shielding gas is used to protect the cut area from atmospheric gases, preventing oxidation and ensuring a clean and smooth cut.

Benefits of the Right Shielding Gas

- Improved cutting quality and finish

- Reduced risk of oxidation and porosity

- Increased efficiency and productivity

6. Torch Height

The torch height is critical when it comes to cutting with a torch. Maintaining the right torch height will ensure a smooth and even cut, while preventing overheating or warping the material.

Benefits of the Right Torch Height

- Improved cutting quality and finish

- Reduced risk of overheating or warping the material

- Increased efficiency and productivity

7. Post-Heat Treatment

Post-heat treatment is essential for achieving a smooth and even finish. This involves slowly cooling the material after cutting, preventing warping or distortion.

Benefits of Post-Heat Treatment

- Improved cutting quality and finish

- Reduced risk of warping or distortion

- Increased efficiency and productivity

Torch Settings for Cutting Image Gallery

By following these 7 essential torch settings for cutting, you'll be able to achieve professional-looking cuts with ease. Remember to always use caution and follow safety guidelines when working with a torch. With practice and patience, you'll become a master of torch cutting in no time!

What's your favorite torch setting for cutting? Share your experiences and tips in the comments below!