Intro

Master process control with our expert guide on how to calculate Cpk in Excel. Learn a step-by-step approach to measuring process capability and stability using Excel formulas and functions. Discover how to calculate Cpk, Cp, and Pp to optimize process performance and reduce variability. Boost quality control and decision-making with data-driven insights.

In the world of manufacturing and quality control, understanding the performance of a process is crucial for ensuring the production of high-quality products. One widely used metric for evaluating process performance is the Process Capability Index, or Cpk. In this article, we will explore what Cpk is, its importance, and provide a step-by-step guide on how to calculate Cpk in Excel.

Understanding Cpk

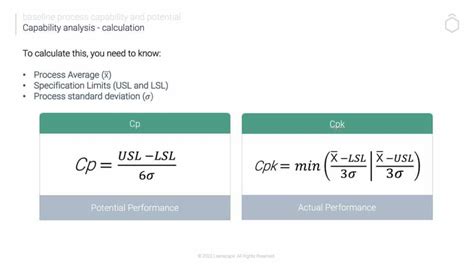

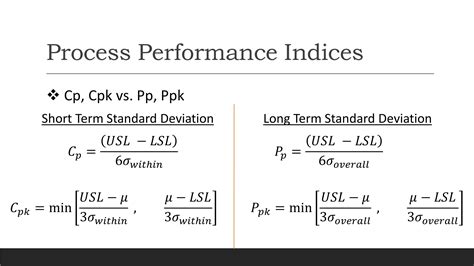

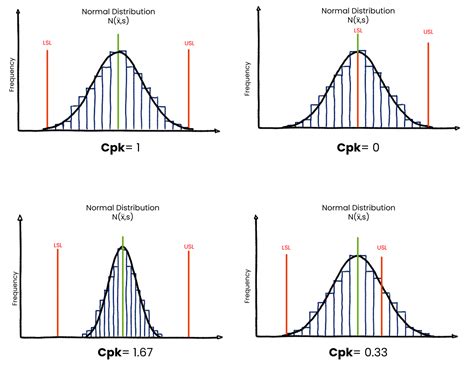

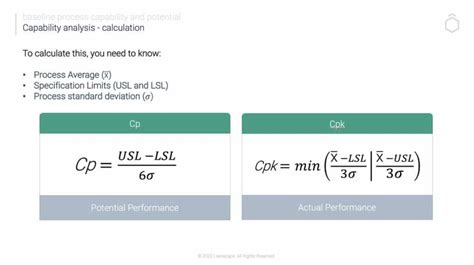

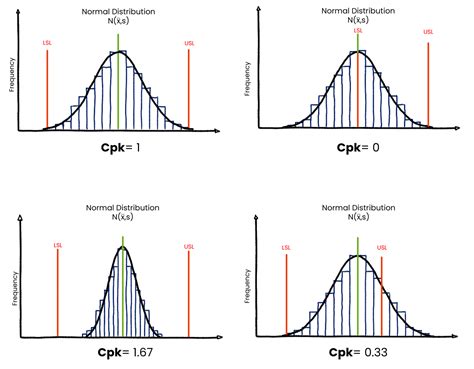

Process capability, or Cpk, is a statistical measure that quantifies a process's ability to produce output within specified limits. It's a ratio of the spread of the process data to the width of the specification limits. Cpk is calculated using the mean, standard deviation, and the upper and lower specification limits (USL and LSL).

Why is Cpk Important?

Cpk is essential in manufacturing as it helps to:

- Evaluate the performance of a process

- Identify potential problems and opportunities for improvement

- Ensure that products meet specifications

- Compare different processes or machines

Calculating Cpk in Excel

Calculating Cpk in Excel involves several steps:

Step 1: Prepare Your Data

Collect data from your process and enter it into an Excel spreadsheet. Ensure that the data is clean and free from errors.

Step 2: Calculate the Mean

Calculate the mean of your data using the AVERAGE function.

Step 3: Calculate the Standard Deviation

Calculate the standard deviation of your data using the STDEV.S function.

Step 4: Calculate the USL and LSL

Enter the upper and lower specification limits (USL and LSL) into separate cells.

Step 5: Calculate Cpk

Use the following formula to calculate Cpk:

Cpk = min((USL - Mean) / (3 * Standard Deviation), (Mean - LSL) / (3 * Standard Deviation))

You can also use the following Excel formula:

=MIN((USL-AVERAGE(data))/3/STDEV.S(data),(AVERAGE(data)-LSL)/3/STDEV.S(data))

Step 6: Interpret Your Results

Interpret your Cpk results:

- A Cpk value of 1.33 or higher indicates that the process is capable of producing output within specifications.

- A Cpk value between 1 and 1.33 indicates that the process is marginally capable.

- A Cpk value below 1 indicates that the process is not capable.

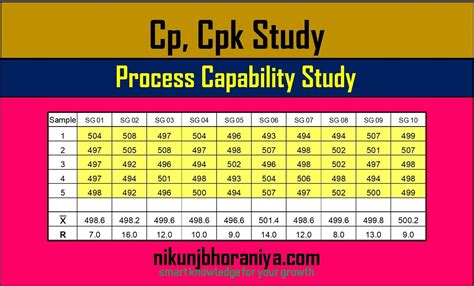

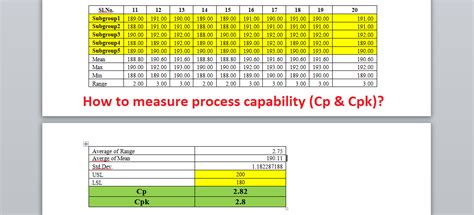

Example Calculation

Suppose we have a process with the following data:

| Data Point | Value |

|---|---|

| 1 | 10.2 |

| 2 | 10.5 |

| 3 | 10.1 |

| 4 | 10.3 |

| 5 | 10.4 |

The USL is 11, and the LSL is 9.5.

Using the steps above, we can calculate the mean and standard deviation:

Mean = 10.3 Standard Deviation = 0.15

Next, we calculate Cpk using the formula:

Cpk = min((11 - 10.3) / (3 * 0.15), (10.3 - 9.5) / (3 * 0.15)) = 1.22

Conclusion

Calculating Cpk in Excel is a straightforward process that requires careful attention to detail. By following these steps, you can evaluate the performance of your process and identify opportunities for improvement.

Gallery of Cpk Calculation

Cpk Calculation Image Gallery

FAQ

Q: What is Cpk? A: Cpk is a statistical measure that quantifies a process's ability to produce output within specified limits.

Q: Why is Cpk important? A: Cpk is essential in manufacturing as it helps to evaluate the performance of a process, identify potential problems, and ensure that products meet specifications.

Q: How do I calculate Cpk in Excel? A: Calculate the mean, standard deviation, and upper and lower specification limits (USL and LSL). Then, use the Cpk formula to calculate the index.

We hope this article has helped you understand Cpk and how to calculate it in Excel. Share your experiences and questions in the comments below!