Intro

Unlock the power of process capability analysis with our step-by-step guide on how to calculate Cpk in Excel using a simple formula. Learn how to measure process performance, detect variability, and improve yield with this essential statistical tool. Master Cpk calculations and take your quality control to the next level.

Understanding Cpk and Its Importance in Quality Control

In the world of quality control, measuring process capability is crucial to ensure that products meet customer specifications. One widely used metric to evaluate process capability is the Cpk (Centered Process Capability Index). In this article, we'll delve into the concept of Cpk, its importance, and provide a step-by-step guide on how to calculate Cpk in Excel using a simple formula.

The Cpk metric assesses the ability of a process to produce output within specified limits, taking into account the process's average performance and variability. It provides a comprehensive view of the process's capability, allowing quality control professionals to identify areas for improvement.

What is Cpk?

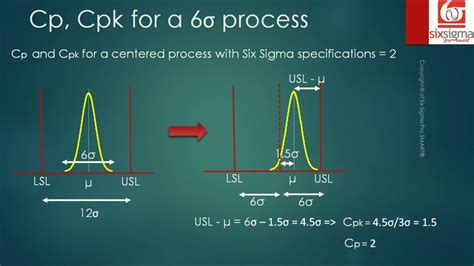

Cpk is a statistical measure that compares the process's average performance to its variability. It's calculated using the process's mean, standard deviation, and specification limits. The Cpk value indicates how well the process is centered within the specification limits, with higher values indicating better process capability.

Calculating Cpk in Excel: A Simple Formula

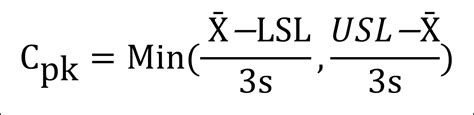

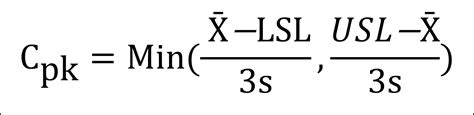

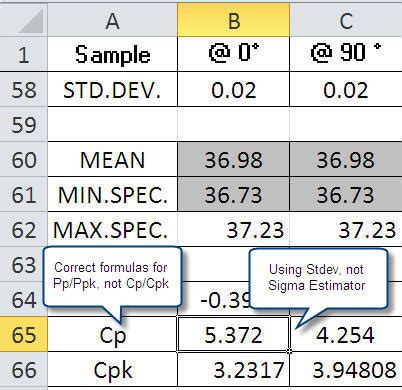

Calculating Cpk in Excel is a straightforward process. Here's the simple formula:

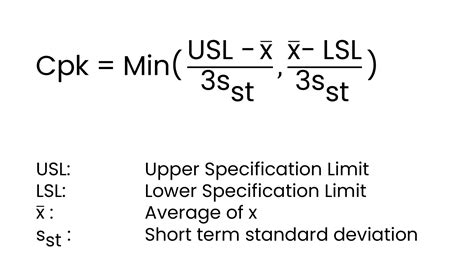

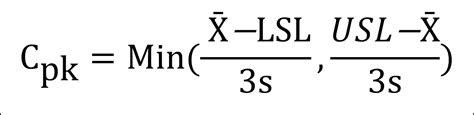

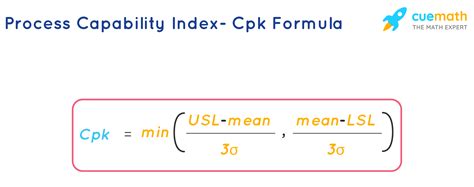

Cpk = (USL - x̄) / (3 * σ) or (x̄ - LSL) / (3 * σ)

Where:

- USL = Upper Specification Limit

- x̄ = Process mean

- σ = Process standard deviation

- LSL = Lower Specification Limit

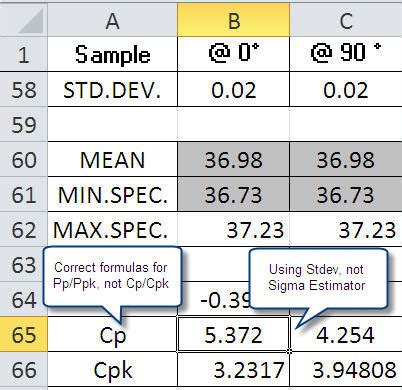

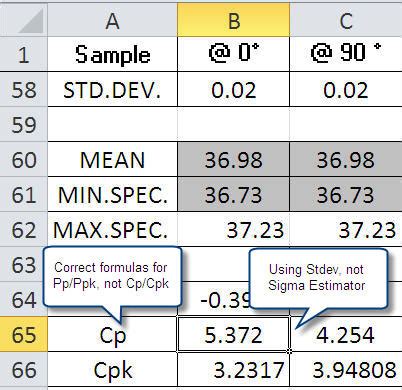

Step-by-Step Guide to Calculating Cpk in Excel

- Determine the specification limits: Identify the upper and lower specification limits (USL and LSL) for the process.

- Calculate the process mean: Use the AVERAGE function in Excel to calculate the process mean (x̄).

- Calculate the process standard deviation: Use the STDEV function in Excel to calculate the process standard deviation (σ).

- Enter the formula: Enter the Cpk formula in a cell, using the values calculated in steps 1-3.

- Calculate the Cpk value: Excel will calculate the Cpk value based on the formula.

Example:

| Process Data | 10.2 | 10.5 | 10.8 | 10.1 | 10.6 |

|---|---|---|---|---|---|

| Mean (x̄) | 10.44 | ||||

| Standard Deviation (σ) | 0.21 | ||||

| USL | 11.0 | ||||

| LSL | 9.0 |

Using the formula:

Cpk = (11.0 - 10.44) / (3 * 0.21) = 1.43

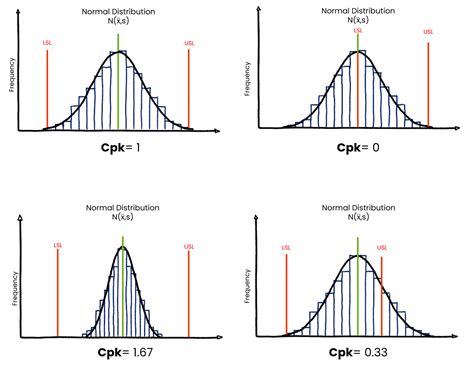

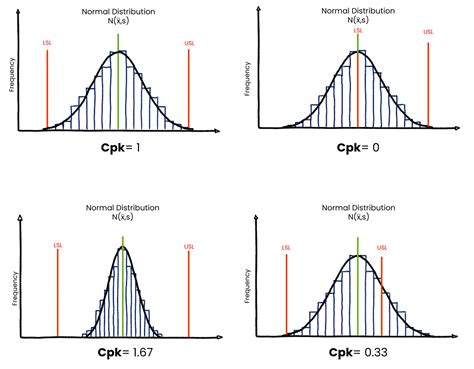

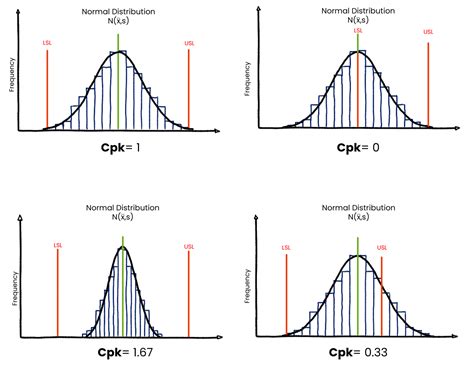

Interpreting Cpk Values

Cpk values can be interpreted as follows:

- Cpk ≥ 1.33: The process is capable and centered.

- 1.00 ≤ Cpk < 1.33: The process is capable but not centered.

- Cpk < 1.00: The process is not capable.

In the example above, the Cpk value of 1.43 indicates that the process is capable and centered.

Common Challenges in Calculating Cpk

- Non-normal data distribution: Cpk assumes a normal distribution of data. If the data is not normally distributed, alternative methods such as Ppk (Process Performance Index) may be used.

- Insufficient data: A minimum of 30 data points is recommended to calculate Cpk. With fewer data points, the calculation may not be reliable.

Best Practices for Calculating Cpk

- Use a sufficient sample size: Use at least 30 data points to calculate Cpk.

- Verify data normality: Check if the data is normally distributed before calculating Cpk.

- Use the correct formula: Use the correct formula for Cpk, taking into account the process's mean, standard deviation, and specification limits.

Cpk Formula and Interpretation Image Gallery

We hope this article has provided you with a comprehensive understanding of Cpk and its calculation in Excel. By following the simple formula and best practices outlined above, you can effectively calculate Cpk and improve your process capability. If you have any questions or need further clarification, please don't hesitate to comment below.