Intro

Optimize your inventory management with the Min-Max formula, a powerful technique for determining optimal stock levels. Learn how to calculate reorder points, minimize stockouts and overstocking, and maximize profits. Discover the benefits of implementing Min-Max in your inventory control strategy, including reduced costs, improved efficiency, and enhanced supply chain management.

Effective inventory management is crucial for businesses to maintain a competitive edge, reduce costs, and enhance customer satisfaction. One popular approach to optimize inventory management is the Min-Max formula. In this article, we will delve into the world of inventory management, explore the Min-Max formula, and discuss its benefits, implementation, and best practices.

Inventory management involves balancing the level of inventory to meet customer demand while minimizing costs. The Min-Max formula is a widely used technique to determine the optimal inventory levels. It takes into account the minimum and maximum inventory levels, ensuring that the business has sufficient stock to meet customer demand while avoiding overstocking.

Understanding the Min-Max Formula

The Min-Max formula is based on the concept of minimum and maximum inventory levels. The minimum inventory level (Min) is the lowest level of inventory that a business can maintain without running out of stock. The maximum inventory level (Max) is the highest level of inventory that a business can maintain without overstocking.

The Min-Max formula is calculated as follows:

Min = (Lead Time x Demand) / (1 - Service Level)

Max = (Lead Time x Demand) / (1 - Service Level) + Safety Stock

Where:

- Lead Time is the time it takes to receive new inventory

- Demand is the average daily demand

- Service Level is the desired service level, usually expressed as a percentage

- Safety Stock is the additional inventory held to meet unexpected demand

Benefits of the Min-Max Formula

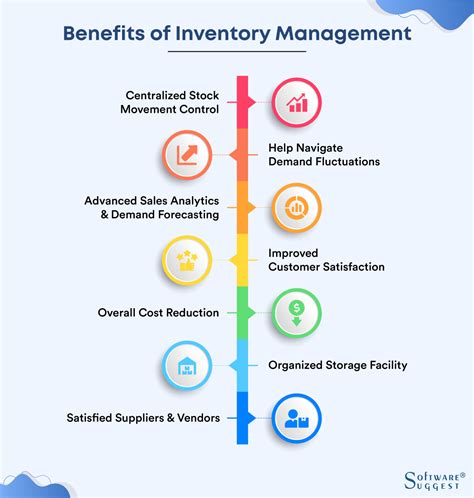

The Min-Max formula offers several benefits to businesses, including:

- Improved inventory management: By determining the optimal inventory levels, businesses can reduce stockouts, overstocking, and associated costs.

- Increased efficiency: The Min-Max formula helps businesses to streamline their inventory management processes, reducing the need for manual intervention.

- Enhanced customer satisfaction: By maintaining optimal inventory levels, businesses can ensure that they have sufficient stock to meet customer demand, leading to increased customer satisfaction.

- Cost savings: The Min-Max formula helps businesses to reduce inventory costs, including holding costs, ordering costs, and stockout costs.

Implementing the Min-Max Formula

Implementing the Min-Max formula requires a few steps:

- Determine the lead time: Calculate the time it takes to receive new inventory.

- Determine the demand: Calculate the average daily demand.

- Determine the service level: Decide on the desired service level, usually expressed as a percentage.

- Determine the safety stock: Calculate the additional inventory held to meet unexpected demand.

- Calculate the Min and Max levels: Use the formula to calculate the minimum and maximum inventory levels.

- Monitor and adjust: Continuously monitor inventory levels and adjust the Min and Max levels as needed.

Best Practices for the Min-Max Formula

To get the most out of the Min-Max formula, follow these best practices:

- Regularly review and update demand forecasts to ensure accuracy.

- Monitor lead times and adjust the formula accordingly.

- Adjust the service level and safety stock levels based on business requirements.

- Consider implementing a just-in-time (JIT) inventory system to reduce inventory levels.

- Continuously monitor inventory levels and adjust the Min and Max levels as needed.

Common Challenges and Limitations

While the Min-Max formula is a powerful tool for inventory management, it is not without its challenges and limitations. Some common challenges include:

- Difficulty in determining accurate demand forecasts

- Fluctuations in lead times and supplier reliability

- Inadequate safety stock levels

- Insufficient data and analytics

Overcoming Challenges and Limitations

To overcome these challenges and limitations, consider the following strategies:

- Implement a robust demand forecasting system

- Develop strong relationships with suppliers to ensure reliable lead times

- Continuously monitor and adjust safety stock levels

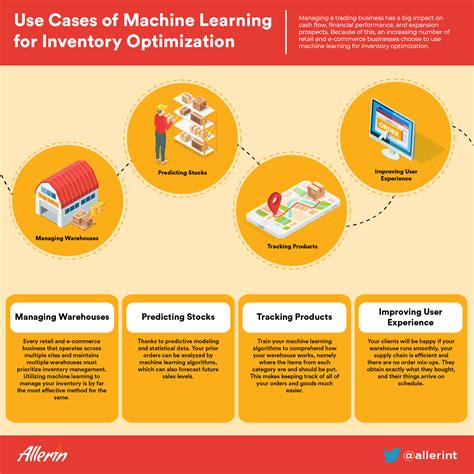

- Invest in data analytics and inventory management software

Conclusion

In conclusion, the Min-Max formula is a powerful tool for inventory management optimization. By determining the optimal inventory levels, businesses can reduce costs, enhance customer satisfaction, and improve efficiency. While there are challenges and limitations to consider, by following best practices and implementing strategies to overcome these challenges, businesses can unlock the full potential of the Min-Max formula.

Inventory Management Optimization Image Gallery

We hope this article has provided valuable insights into the Min-Max formula and its application in inventory management optimization. If you have any questions or would like to share your experiences, please leave a comment below.