Intro

Discover alternative sourcing options beyond China. Learn about the benefits and challenges of nearshoring, reshoring, and global sourcing from countries like Vietnam, Mexico, and Eastern Europe. Explore the impact of trade policies, tariffs, and supply chain disruptions on your business and find a reliable sourcing strategy that meets your needs.

The "Made in China" label has become ubiquitous in global trade, with China being the world's largest exporter of goods. However, in recent years, many businesses and consumers have begun to explore alternative sourcing options. This shift is driven by various factors, including concerns over quality, intellectual property, labor practices, and trade tensions. In this article, we will delve into the world of Not Made in China and explore the benefits and challenges of sourcing from alternative countries.

Why Look Beyond China?

China's dominance in global trade is undeniable, but it also comes with its own set of challenges. Some of the key reasons why businesses are looking beyond China include:

- Quality concerns: While China has made significant strides in improving product quality, some industries still struggle with inconsistent quality control.

- Intellectual property risks: China has faced criticism for not doing enough to protect intellectual property rights, which can be a major concern for businesses that rely on innovative products.

- Labor practices: China has faced criticism for its labor practices, including allegations of forced labor and poor working conditions.

- Trade tensions: The ongoing trade tensions between the US and China have led to increased tariffs and uncertainty for businesses that rely on Chinese imports.

Benefits of Alternative Sourcing

Sourcing from alternative countries can offer several benefits, including:

- Diversification: Sourcing from multiple countries can reduce dependence on a single market and mitigate risks associated with trade tensions or supply chain disruptions.

- Improved quality: Some countries have a reputation for producing high-quality products, which can be attractive to businesses that prioritize quality.

- Increased flexibility: Working with suppliers from different countries can provide more flexibility in terms of production capacity, lead times, and pricing.

- Better labor practices: Some countries have stronger labor laws and regulations, which can be attractive to businesses that prioritize social responsibility.

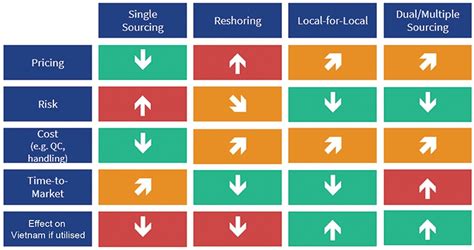

Alternative Sourcing Options

So, where can businesses look for alternative sourcing options? Here are some countries that are gaining traction:

- Vietnam: Vietnam has emerged as a popular alternative to China, with its proximity to China, relatively low labor costs, and favorable business environment.

- India: India has a large and skilled workforce, making it an attractive option for businesses that require complex manufacturing or IT services.

- Mexico: Mexico's proximity to the US and favorable trade agreements make it an attractive option for businesses that want to reduce shipping times and costs.

- Thailand: Thailand has a well-established manufacturing sector, with a strong focus on automotive and electronics production.

- Poland: Poland has a highly skilled workforce and a favorable business environment, making it an attractive option for businesses that require complex manufacturing or IT services.

Challenges of Alternative Sourcing

While alternative sourcing options can offer several benefits, there are also challenges to consider:

- Higher costs: Sourcing from alternative countries can be more expensive than sourcing from China, particularly for labor-intensive products.

- Language barriers: Communication can be a challenge when working with suppliers from different countries, particularly if there are language barriers.

- Logistical challenges: Sourcing from alternative countries can require more complex logistics, including transportation and warehousing.

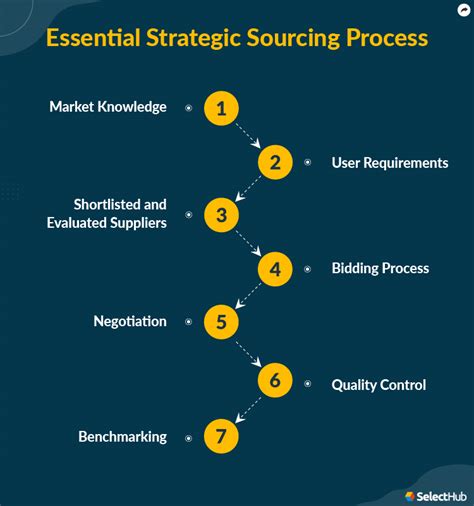

Best Practices for Alternative Sourcing

To succeed in alternative sourcing, businesses should follow best practices, including:

- Conduct thorough research: Research potential suppliers thoroughly, including their reputation, quality control processes, and labor practices.

- Build relationships: Build strong relationships with suppliers, including regular communication and visits to their facilities.

- Monitor quality: Monitor product quality closely, including regular inspections and testing.

- Plan for logistics: Plan for logistical challenges, including transportation and warehousing.

Conclusion: The Future of Alternative Sourcing

The Not Made in China movement is gaining momentum, driven by concerns over quality, intellectual property, labor practices, and trade tensions. While alternative sourcing options can offer several benefits, including diversification, improved quality, and increased flexibility, there are also challenges to consider, including higher costs, language barriers, and logistical challenges. By following best practices and conducting thorough research, businesses can succeed in alternative sourcing and reduce their dependence on Chinese imports.

Alternative Sourcing Image Gallery